Maximizing Accuracy, Reliability and Speed in PCB Assembly Test

ATE 101

You've just designed a cutting-edge electronic device packed with innovative features and ready to take the world by storm. But before it hits the market, there's a crucial step - testing. How do you ensure your creation works flawlessly, meets all quality standards, and doesn't become a nightmare for users? The answer lies in the use of Automated Test Equipment (ATE), a powerful tool in electronic testing.

What is Structural Testing?

Structural test primarily focuses on the physical connections and structures of a Printed Circuit Board Assembly (PCBA) (unlike its counterpart, functional testing, which verifies if an electronic assembly performs its intended function). Structural test validates that components are accurately placed, soldered, and interconnected, free from defects like shorts, opens, or incorrect component values.

Types of Structural Test

In-Circuit Test (ICT) |

|

|

| Boundary Scan (JTAG) Test |

|

|

| Flying Probe Test (FPT) |  |

|

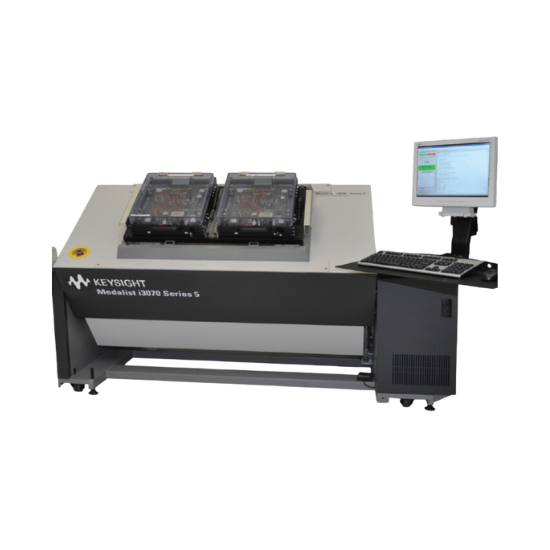

ATE Components

An ATE setup consists of several essential components:

1. Controller - serves as the central processing unit of an ATE system. It manages the test process, communicates with the device-under-test, coordinates the operation of various instruments, and executes the test sequences.

2. Test Instruments - some instruments include: measurement systems, power supplies, signal generators.

3. Software - part of an ATE that handles the automation. It creates and executes test sequences, gathers data, and generates detailed reports.

4. Test Fixture - securely holds and connects devices or circuit assemblies to the automated test equipment.

Benefits of Using an ATE

ATEs give manufacturers confidence in their production quality, allowing them to consistently ship high-quality products by catching manufacturing defects before it's too late.

1. Accuracy and Consistency - ATEs execute tests accurately and consistently, eliminating human errors

2. Efficiency and Speed - manual testing is slow and inefficient, often causing delays in product shipments. An ATE reduces manual testing procedures to mere minutes or even seconds, ensuring timely product deliveries

3. Comprehensive Testing ATEs allow manufacturers to evaluate their electronic devices' functionality, performance, and reliability across various test scenarios

4. Improved Product Quality - using an ATE, you can catch defects at a stage with minimal correction costs. This reduces the chances of costly product recalls or warranty claims.

Comprehensive testing with ATEs is a critical electronic device manufacturing process component. It's a proactive strategy for identifying and addressing issues early and delivering products that consistently meet or exceed consumer expectations. As the complexity of electronic devices continues to evolve, ATEs remain indispensable for quality control and ensuring devices perform seamlessly in the real world.

ATE Applications Across Industries

ATEs are essential tools in various industries. In semiconductors, they ensure integrated circuits meet performance and functionality specs. ATEs test avionics, radar, and missile systems for reliability in aerospace and defense. The automotive sector relies on ATEs for components like ECUs and sensors. Telecommunications uses them to evaluate networking equipment, while healthcare employs ATEs to verify medical device accuracy. For consumer electronics, ATEs are essential to meet quality standards in devices like smartphones and tablets.

16 Key Considerations When Choosing an ATE

Defining your objectives, establishing a realistic budget, and assessing various factors are essential when considering an ATE. These factors include speed, coverage, scalability, flexibility, reliability, regulatory compliance, cost of ownership, user-friendliness, test interface quality, safety features, and support for prototyping, research, and development.

|

|

|

|

Test Objectives

Define the key functions and features for testing, such as power consumption, voltage levels, digital logic, analog signals, and communication interfaces. |

Budget

Set a realistic budget that covers initial purchase costs, ongoing expenses, maintenance, and potential upgrades. |

Test Coverage

Evaluate the extent of test coverage needed to examine devices thoroughly. Comprehensive coverage is crucial for identifying defects and ensuring product quality.

|

Throughput

Determine your expected testing volume and product mix |

|

|

|

|

Scalability

Anticipate future testing volume growth. Choose a scalable ATE system to avoid future equipment replacement or upgrades. |

Flexibility

Opting for a flexible test tool ensures that you can adapt to different testing scenarios and evolving testing procedures without requiring frequent equipment changes. |

ReliabilityAn ATE system with high uptime remains operational when needed, minimizing disruptions to production schedules and reducing test costs.

|

Integration

Confirm that the tester seamlessly integrates with your existing equipment and software, such as Manufacturing Execution Systems (MES) or data analysis tools. |

|

|

|

|

Space Requirements

How much space is available for the tester on your production floor or lab? Are there any restrictions at the entrance that could hinder moving the tester into the space? |

Test Data Management

The capability to save and send test data to the cloud for quality control and analysis to aid decision-making and process improvement. |

Maintenance & SupportEase of maintenance and the availability of support services, such as easy access to replacement parts and responsive customer support, can minimize cost and downtime.

|

Regulatory Compliance

If your industry has specific compliance standards, ensure the tester meets these standards and can provide the necessary certifications. |

|

|

|

|

Total Cost of Ownership

Consider the total cost of ownership, including the initial investment, maintenance, calibration, potential upgrades, savings accrued from decreased labor costs and warranty returns. |

User Interface

The system's user interface should be intuitive and user-friendly, reducing the learning curve for users and minimizing the potential for user input errors. |

SafetyEnsure that the ATE incorporates safety features to protect equipment and personnel during testing operations.

|

Prototype and R&D Support

If testing is necessary during your prototype or research and development stages, ensure that the tester can provide support for these phases. |

Understanding the essentials of Automated Test Equipment (ATE) is fundamental in today's complex electronics landscape. ATEs ensure the quality and reliability of electronic components and contribute significantly to efficiency, cost-effectiveness, and customer satisfaction. The features and considerations outlined here are crucial for manufacturers and engineers, from comprehensive testing and data management to scalability and cost-effectiveness. As technology advances, ATE remains at the forefront, empowering us to create and deliver electronics that meet the highest standards of excellence. Explore the possibilities, embrace automation, and unlock the potential of ATE to drive innovation and elevate your electronic testing processes.