A Powerful Manufacturing Test Solution for Confidence in Your Product Quality

The need to test and ensure product performance continues to be a pivotal factor in getting products to market with the least cost and highest reliability. Product validation processes may require tests and inspections outside the available Automated Test Equipment capabilities.

The Acculogic FLS980Dxi Flying Probe tester opens the door to enhanced circuit board test and inspection capabilities using Acculogic’s new Scorpion Bridge module.

Integration of External Instrumentation

The Scorpion Bridge module enables test engineers to quickly boost their test coverage and design complete test cycles at the lowest cost. How? The Scorpion Bridge provides the capability to connect 64 channels with individual testing capabilities to 64 probes on fully automated shuttles capable of on-the-fly transition from test to test with precision placement on the test location. So, connecting a diverse range of external instruments (such as multimeters, signal generators, programmers, oscilloscopes, and more) to the FLS980Dxi system is inexpensive and quick.

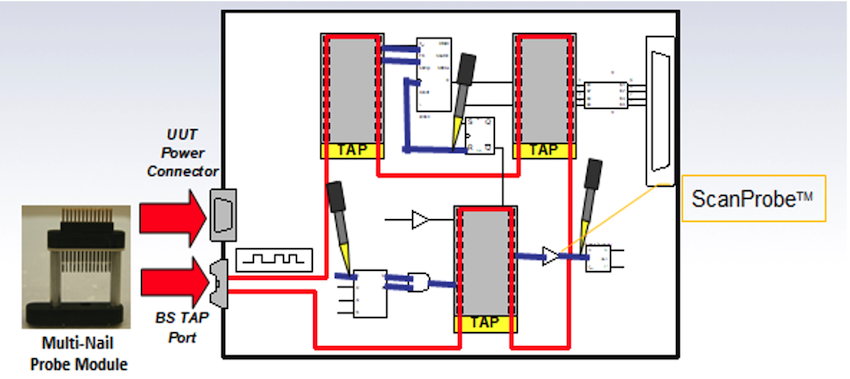

ScanProbe Advanced Boundary Scan Testing

In-Circuit (ICT) Level Test Coverage

The Scorpion Bridge module can switch up to 64 channels to 64 different probe types using a combination of Flying Probes and Flying Fixtures. This is the ideal solution for test applications such as boundary scan, where the moving probes set some nets high or low and measure logic levels, thus dramatically increasing the overall test coverage and throughput.

ScanProbe Advanced Boundary Scan Testing

Single Stage Test & Inspection

In today’s test production line, performing tests such as Boundary Scan, Functional or N tests occur at different test stations. However, with the Scorpion Bridge system, many of these tests can be carried out in a single stage, including Manufacturing Defects Analysis (MDA), Flash Programming, Boundary Scan, Optical, and Functional tests. The ability to execute multiple tests in one fully automated high-speed test system reduces test times by over 47%, making it ideal for high volume or high mix manufacturers who demand maximum test productivity.

High-Speed Test and Factory Automation

Coupling an Automated Inline Board Handler with a Scorpion Bridge equipped FLS980 Flying Prober yields a fully automated, high-speed, in-line test system capable of testing multiple product types.

How it works

After automatically scanning the magazine ID and the PCB Barcode, the circuit board is fed into the tester, which pulls up and executes the associated test program. This system eliminates the need for any manual intervention or operation. In addition, sending test data to a central factory (SAP-Manufacturing Execution Systems) database is done in real-time.

Automatic Pass/Fail Operation & Re-test

Following test completion, the test system writes the Magazine ID, bar code, and test results for each board into the factory database. The system automatically separates the passed boards from the failed ones and routes faulty boards to an available repair station with their corresponding test data. After finalizing the repairs, boards are automatically sent back to the FLS980, where the tester recalls the faults for each board and verifies that the repairs have corrected the defects.

Leading the Way Ahead of the Competition

The Scorpion Bridge module enables the connection of almost any type of external instrument to an FLS980 Flying Probe system. This makes it possible to perform a broad spectrum of test and inspection functions on a Unit Under Test. By delivering industry-leading test coverage capability, the Scorpion Bridge establishes the FLS980 platform as the most advanced, complete, and cost-effective flying probe system available.