Revolutionize Your Battery Testing with Acculogic's Patented Test Technology

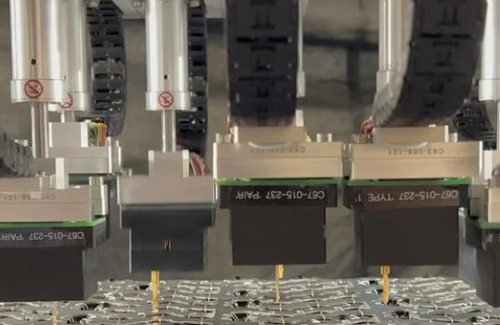

- ➡️ Flexible Testing Methodology

- ➡️ Configurable

- ➡️ Double-sided

- ➡️ Fastest Testing Speed

TRUSTED BY

3 of the Top 10 Battery Manufacturers for Speed and Configurability.

Battery interconnect issues must be caught during battery production. Otherwise, field failures can be costly and harmful to a company’s reputation. For battery manufacturers, it is critical to have a production test solution that can quickly, reliably, and cost-effectively test battery module interconnects.

See the Most Advanced Battery Test Solutions

at the Battery Show North America 2023

Sept. 12-14, 2023 | Novi, Michigan

Visit Acculogic in Booth # 1356

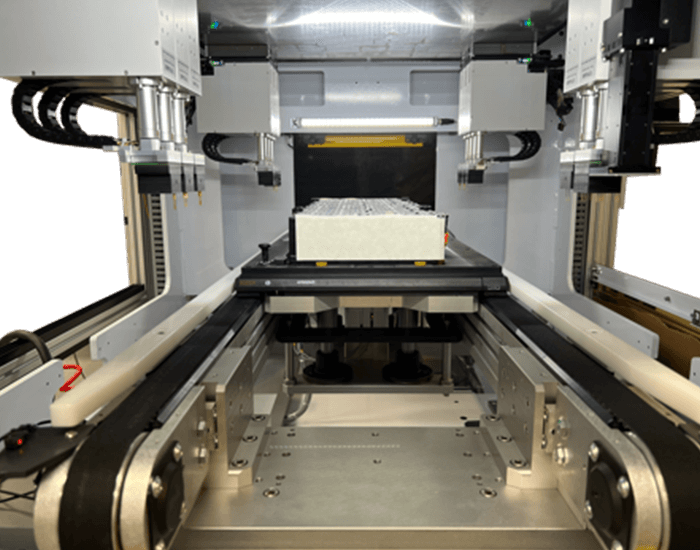

Meet with our team of experts and experience the exceptional STINGRAY EVO500 Automated Battery Tester.

Highlights of the STINGRAY EVO500

Acculogic Customers are meeting their

production requirements and shipping defect-free batteries.

Confidence in product quality

![]() Battery integrity testing is a pivotal step in our production because escaped defects have the potential for causing serious issues downstream. So, being able to identify and correct defects at the earliest stage possible minimizes costly rework and delays.

Battery integrity testing is a pivotal step in our production because escaped defects have the potential for causing serious issues downstream. So, being able to identify and correct defects at the earliest stage possible minimizes costly rework and delays.

Production and prototype testing

![]() With the STINGRAY, we've found a reliable and configurable solution for testing our battery prototypes and full-scale production units.

With the STINGRAY, we've found a reliable and configurable solution for testing our battery prototypes and full-scale production units.

Factory automation

![]() For us to meet our production volume requirements, bringing our test in-line was non-negotiable. Acculogic implemented a solution with customized conveyor systems that keep our production line running smoothly.

For us to meet our production volume requirements, bringing our test in-line was non-negotiable. Acculogic implemented a solution with customized conveyor systems that keep our production line running smoothly.

Our Customers Say That This Is Game-Changing Technology

Independent Robotic Positioning System delivers maximum