END-OF-LINE TESTING

IMPROVE QUALITY. CUT COSTS. SHIP ON-TIME.

What if you came to work today and realized that the production output from the past week that was shipped to your customers had a high failure rate? Well, today is not that day, nor will tomorrow or any days that follow. That’s because your Acculogic functional/EOL tester gives you the confidence to ship defect-free products.

End-of-Line & Functional Tester - Starting Your Project

A well-crafted SoW (Statement of Work) can prevent ambiguities regarding timelines, budgets, success criteria, and deliverable requirements. Preparing a SoW for an End-of-Line Tester project can be complex and time-consuming. We will work closely with you to ensure your SoW is clear and complete.

Acculogic creates a smooth path for you to ship products on time by building technically advanced custom functional and end-of-line board and system-level test systems. So, take the doubt out of your product’s conformance and gain confidence in your product’s performance.

What Sets Acculogic Apart from the Competition?

Sample EOL & Functional Test Projects

Multi-Station End-of-Line Tester & Programming Solution, featuring:

In-line In-Circuit Test & Programming Station, featuring:

Smart Power Inverter EOL Test Station

EOL with True Batch Processing, Dual Well Fixture

End-of Line & Functional Tester Development

Technology & Components

At Acculogic, we leverage the power of National Instruments LabVIEW and NI TestStand to develop custom functional test systems that meet the requirements of our clients.

LabVIEW, a graphical programming language, is the foundation of our functional test system development process. Its extensive libraries and modules allow us to seamlessly interface with a wide range of instruments, devices, and communication protocols. This flexibility enables us to develop tailored test solutions for various industries and applications. LabVIEW's graphical interface makes it easy for our engineers to develop test applications efficiently, reducing development time and costs. With LabVIEW, we can quickly create intuitive and flexible test sequences, define precise test limits, and generate detailed reports. Moreover, LabVIEW's scalability allows us to adapt the test system to changing requirements and easily incorporate additional functionality.

NI TestStand complements LabVIEW by providing a robust framework for test sequencing and execution. It is a centralized platform for organizing and managing test sequences, ensuring efficient test execution and result analysis. TestStand's reporting capabilities enable accurate documentation and easy access to test results, facilitating effective data-driven decision-making. By harnessing the capabilities of LabVIEW and TestStand, we can deliver customized functional test systems that effectively verify your products' functionality.

Our 9-Step EOL & Functional Test System Development Process

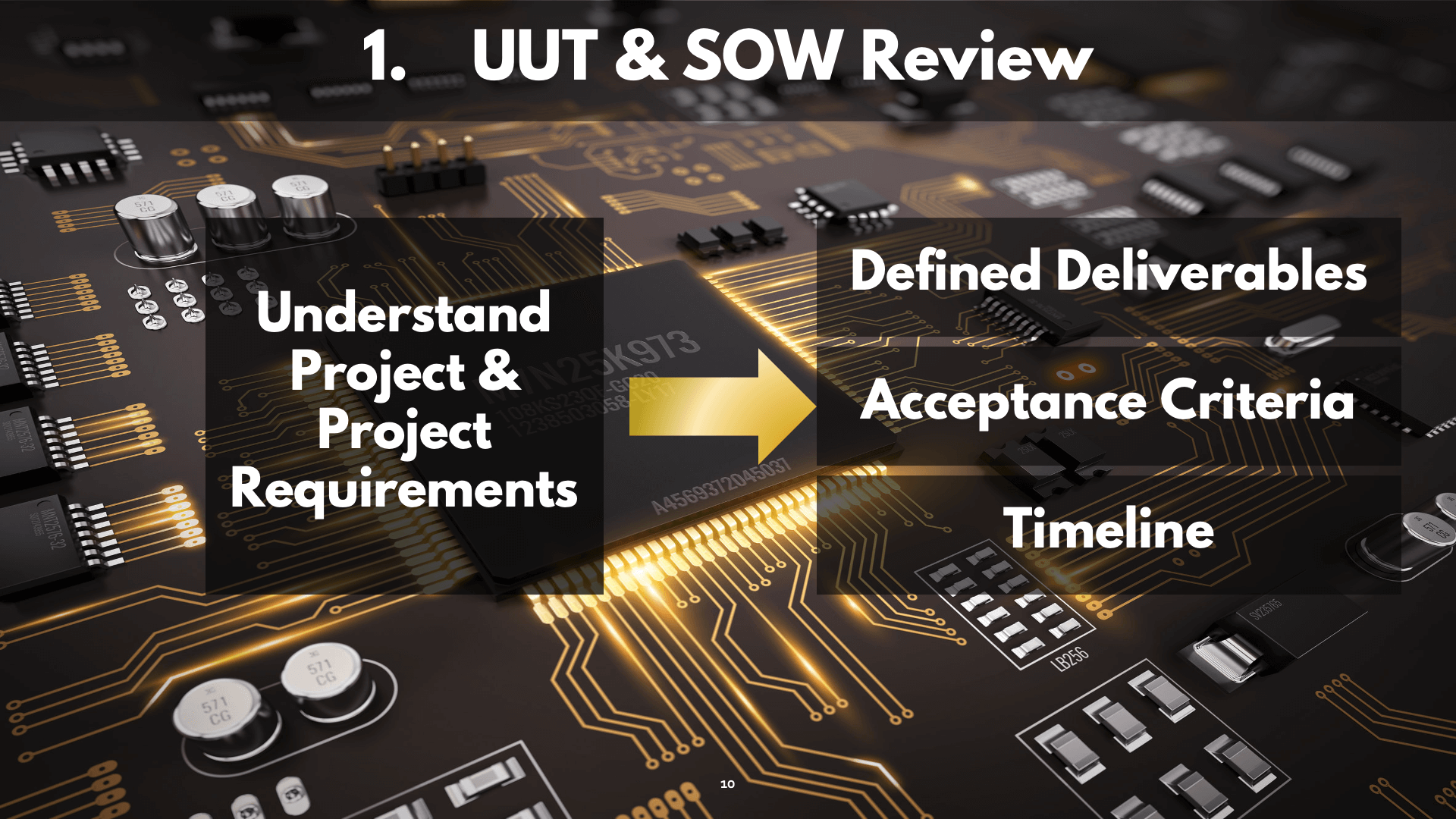

1. Review of the Unit Under Test (UUT) and the Statement of Work (SOW)

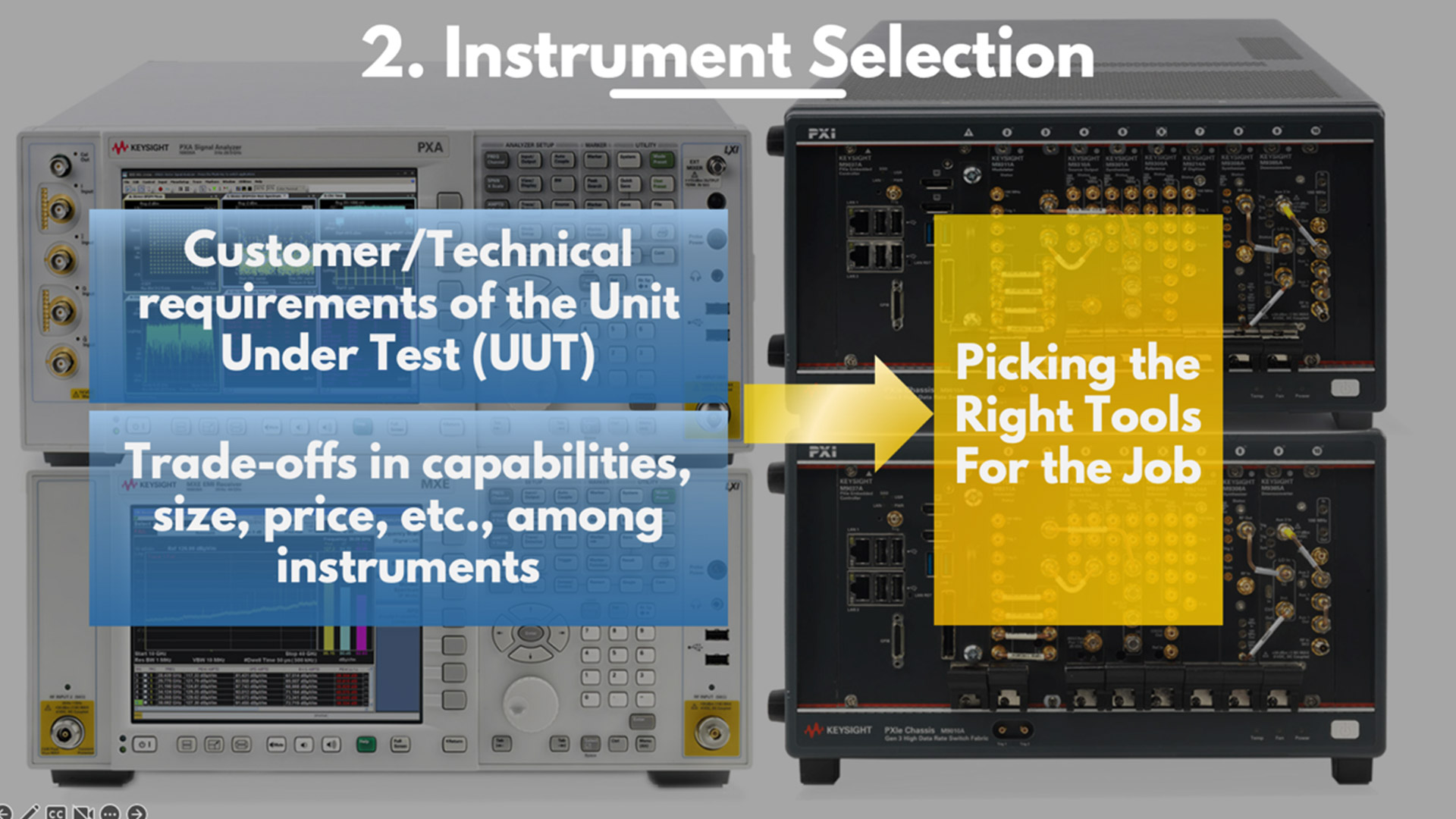

2. Instrument Selection

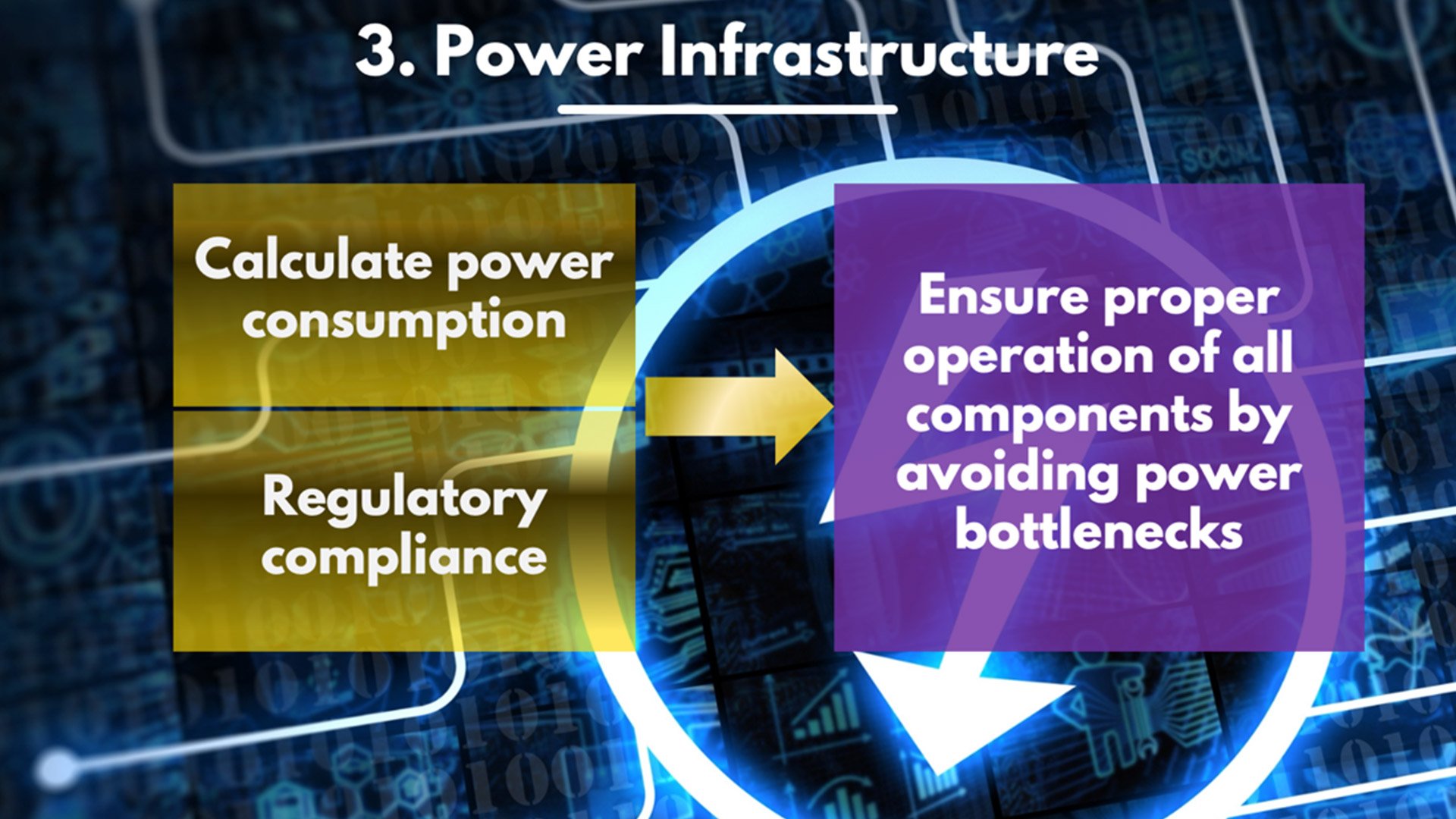

3. Power Infrastructure

4. Switching & Multiplexing

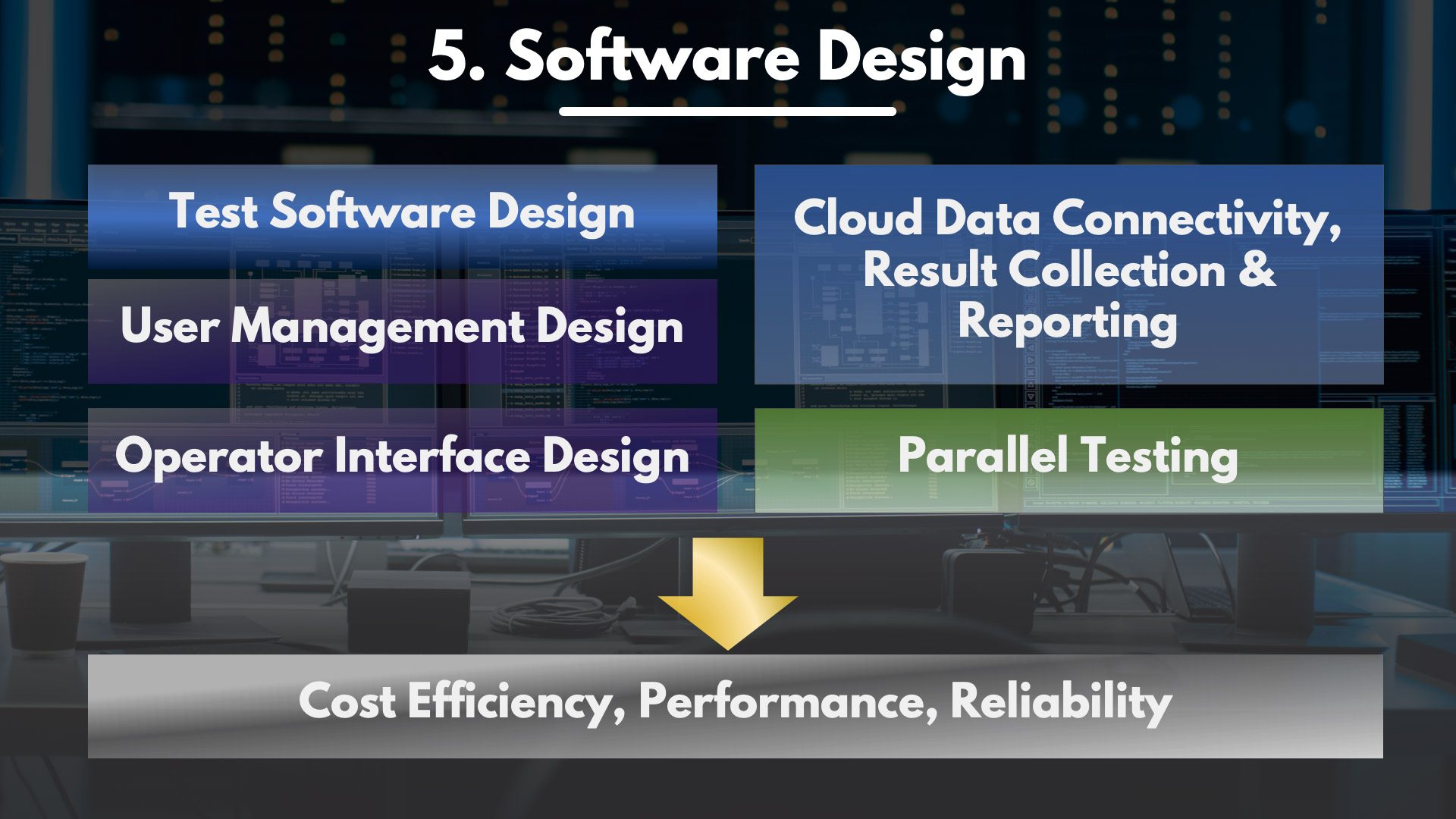

5. Software Design

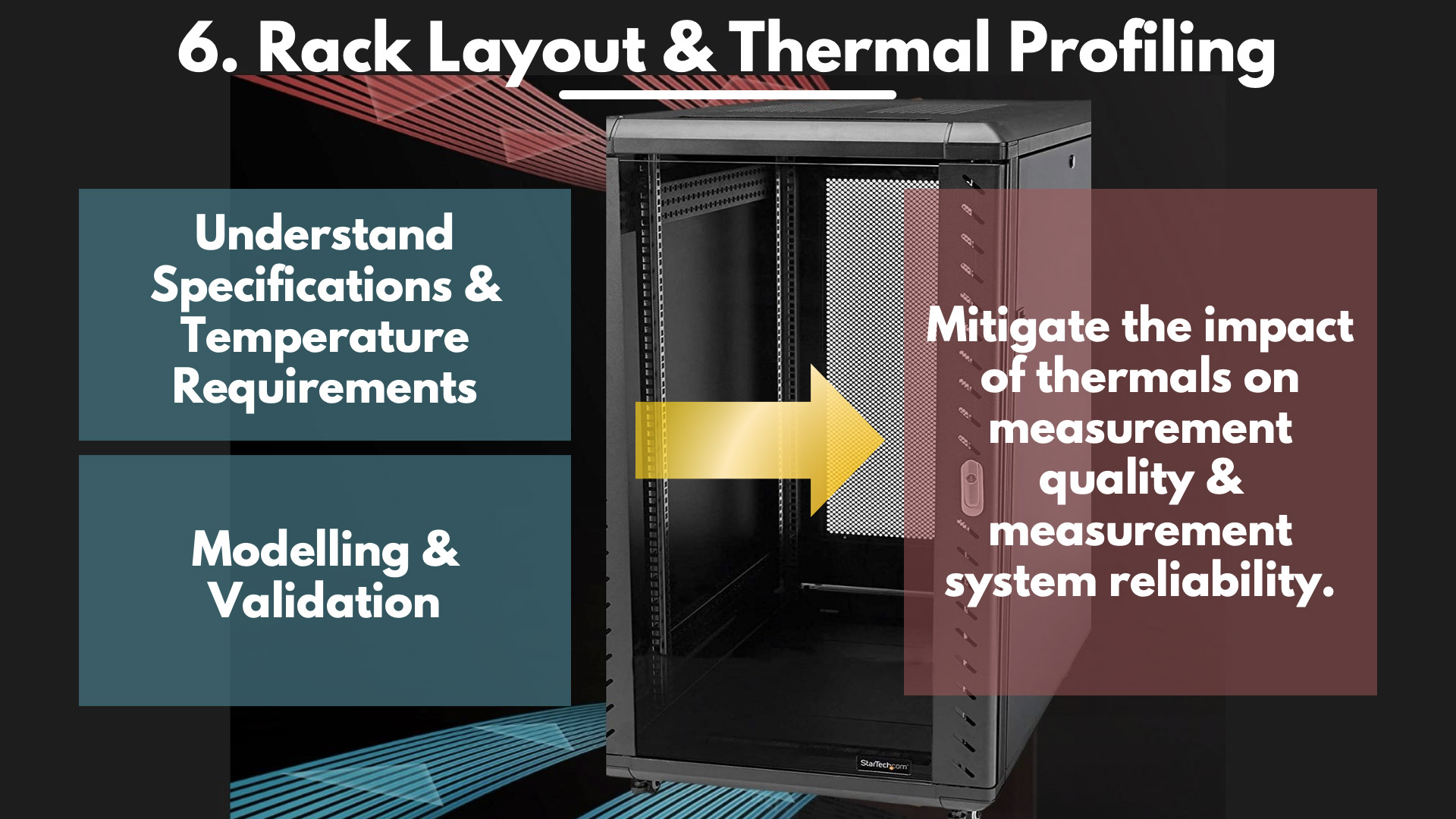

6. Rack Layout & Thermal Profiling

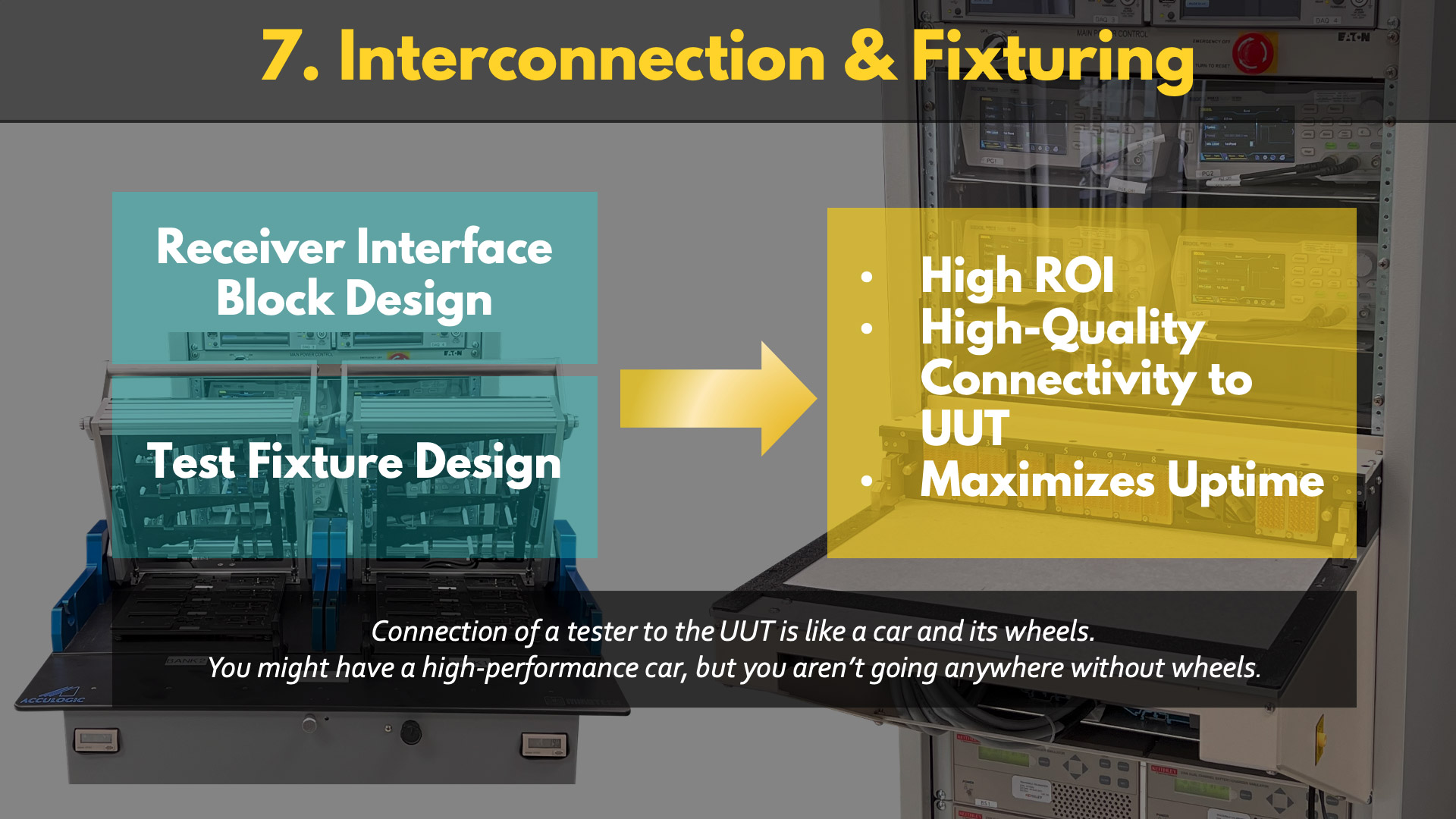

7. Interconnection & Fixturing

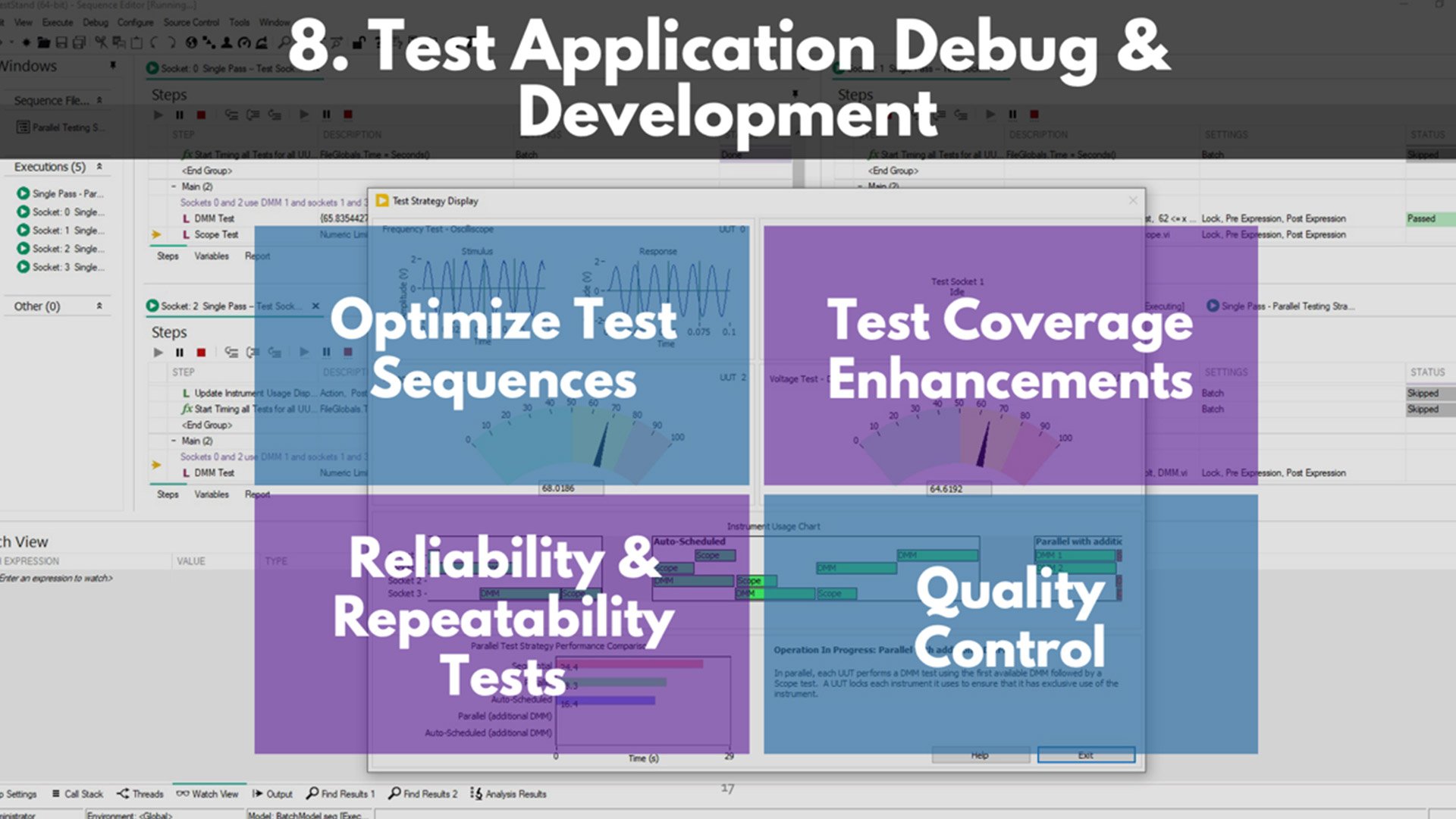

8. Test Application Debug & Development

9. Delivery

WANT MORE REASONS WHY A CUSTOM FUNCTIONAL TESTER FROM ACCULOGIC MAKES SENSE FOR YOU?

Regardless of its complexity or size, test all electronic assemblies.

Achieve your test requirements with multiple measurement characteristics such as:

- Voltage & Current

- Analog & Digital Signals

- LED Test & Characterization

- RF Signal Integrity

Using a proven 9-step process, we’ll deliver your system in the shortest possible time without any compromises.

Reduce labor costs, minimize handling, and boost production capacity. Also, test data can be saved to the cloud and/or automatically entered into your existing databases.

We engineer systems with durability and longevity that are easy to troubleshoot & maintain so you can keep testing.

- Easy to service

- Minimize any downtime

- Fast access to support

- Remote access support

- Scalable architecture

- Modular software

- Easy hardware changes

- Design for maintainability

Reliable testers that are simple to operate and adaptable to your needs.

Find a Better Test Strategy

When you work with Acculogic, you choose a trusted path to ship defect-free products on time with a test strategy that balances your tester and fixture costs, test objectivess, cycle time requirements, and tester development schedule.