See the Most Advanced Battery Test Solutions for Prototype to Production

at the Battery Show North America

October 7-9, 2025 | Huntington Place, Detroit, Michigan

See a live demo!

Visit Acculogic in Booth 3226

Meet with our team of experts and experience the exceptional STINGRAY 940E Automated Battery Tester.

Critical for ensuring the safety, reliability and performance of EV batteries, testing assess the overall performance, capacity, energy density, power output and efficiency.

From prototype to production, in-line testing helps identify defects or inconsistencies early on, allowing you to rectify issues before they reach the market.

With Acculogic Battery Testing Solutions, you can verify the battery meets the required standards for driving range, acceleration, and overall vehicle performance.

STINGRAY

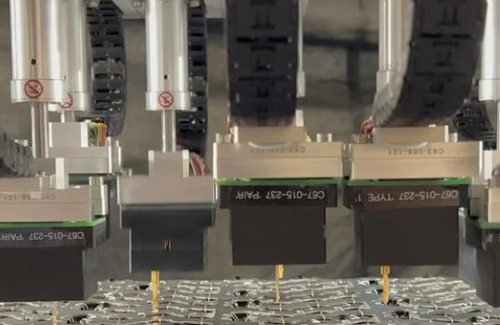

Quick, Reliable, and Cost-Effective Battery Module Interconnect Testing

Test electrical performance, mechanical integrity, thermal management, reliability, safety, and manufacturing quality control of battery packs in electric vehicles.

Gain a commanding advantage with the patented STINGRAY E940E

➡️ Double-sided test

➡️ Fast test speed

➡️ Prototype & Production Use

➡️ Configurable

Join us for a free webinar!

Laser Precision, Testing Issues: Challenges of Testing Laser Welded Batteries

As battery technology continues to evolve, maintaining rigorous quality and safety standards for every weld becomes increasingly challenging. Our knowledgeable speakers will explore the technical obstacles manufacturers face and share possible solutions to address these issues.

Join us October 29 at 11:00AM Eastern.

Non-Contact Interconnect Testing

Acculogic’s patent pending Hover Sense non-contact test technology is an innovative approach to battery interconnect testing available with Acculogic's STINGRAY EVO Battery Testers. This test method uses advanced magnetic field measurement techniques to assess the interconnect quality without physical contact.

The non-destructive nature of contactless testing eliminates the risk of surface degradation and probe markings. By offering a non-destructive and highly efficient testing solution, this technology enhances the safety and performance of EV batteries. It streamlines the testing process, reducing costs and increasing production throughput.

Acculogic's EV Inverter Test solutions validate their performance and reliability before integration into the car.